Newsroom

Why does lime rotary kiln use mine resources better?

2017-09-29 | Editor:

As a basic material for smelting, chemical, construction, medical and health care, thermal power plant desulfurization and other industries, active lime has a very broad market prospect. With the development of economy in our country, higher requirements are put forward for active lime kiln.

Learn more about CHAENG rotary kiln, please visit CHAENG machinery website: http://chaeng.co/

Activated lime kiln is the key equipment for active lime production. Combined with the current situation and development trend of China's economic development, lime kiln should be large-scale, automated, comprehensive utilization of circular economy development.

The traditional vertical kiln requires material blocks not bigger than 40mm, however in limestone mining, only 3/1 of ore blocks are generally smaller than 40mm. Lime rotary kiln can burn gravel materials bigger than 10mm. The lime rotary kiln is applicable more raw materials, which not only can greatly reduce the cost of raw materials, but also can improve the utilization of mineral resources. In the comprehensive utilization of mineral resources, the rotary kiln has great advantages.

Since 1958, CHAENG has been committed to providing active lime calcination equipment with reliable quality and effective cost for customers. The new lime rotary kiln researched and developed by CHAENG wins the trust of customers, and is very popular in the market.

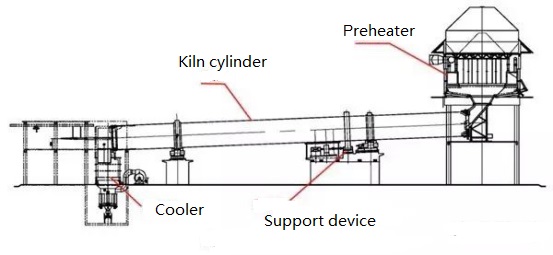

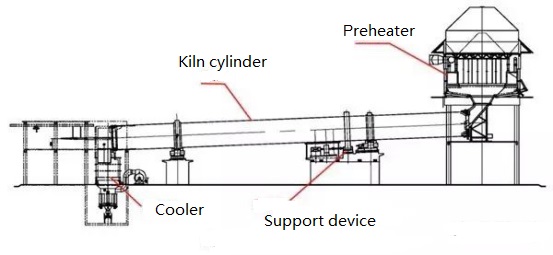

New lime rotary kiln of CHAENG is composed of cylinder, support device, variable speed transmission device, thrust roller device, kiln tail and kiln head seal, kiln head cover. The kiln is inclined to level plane, equipped with two sets of support roller device, the support roller bearing is water-cooled lubrication sliding bearing, and its spherical tile can automatically adjust the center of gravity. Near the ring gear, the support roller is also equipped with hydraulic thrust roller. The kiln body is driven by the variable frequency speed governing motor and auxiliary drive. Kiln tail and kiln head are sealed by spring. The frequency conversion motor is used to drive the kiln body and the decomposition rate of the preheater is adopted to effectively control the calcining time and the temperature, so as to meet the requirements of the over burning and over burning.

CHAENG lime rotary kiln structure is advanced, can quickly improve the effect of preheating, increase the decomposition rate of calcium carbonate, with high fuel calorific value and low fuel consumption amount. Welcome customers to visit CHAENG.

Learn more about CHAENG rotary kiln, please visit CHAENG machinery website: http://chaeng.co/

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:[Share] Measures of Energy Saving and Emission Reduction in Cement Plant (2)

Next:Large Ball Mill & Rotary Kiln Girth Gear Manufacturer in China

PRODUCTS

CONTACT

- Tel: +8615290747879

- Whatsapp: +8615290747879

- E-mail: casting@chaeng.co

- Skype : GreatWall1958