Newsroom

The Rotor of Vertical Roller Mill

2015-07-20 | Editor:

The Rotor, we manufacture, are availible for all kinds of vertical roller mill. It is used as part of the powder concentrator installed the mill. The rough moulding is manufactured by our casting factory--Great Wall Steel Casting Company. Beside this, we have over more than 500 machining equipment to produce the spare parts. Because of which, we can offer you the best quality spare parts with the lowest costs in the markets. As long as you offer a drawing, we can do it perfectly and precisely according to your need.

4, Fill the mold cavity with molten metal;

5, Allow the metal to cool;

6, Heat treatment;

7, Chemical composition test, UT/MT test, mechanical test and so on.

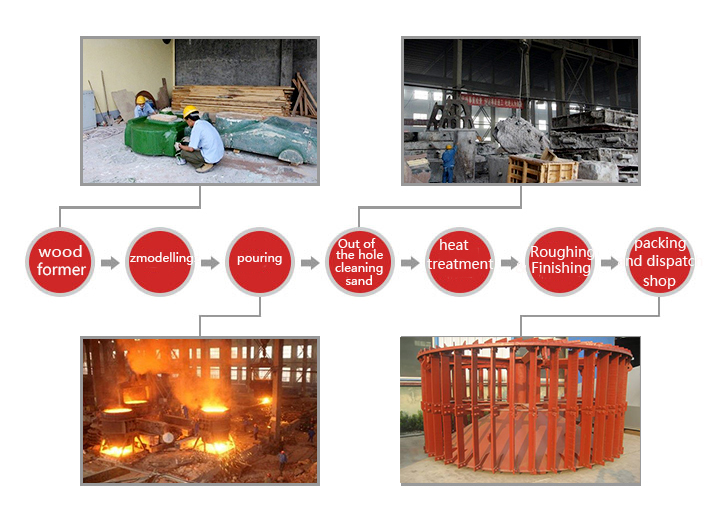

Manufacturing processes of vertical roller mill rotor

1, Place a patten in sand to creat a mold;

2, Incorporate a gating system;

3, Remove the pattern;4, Fill the mold cavity with molten metal;

5, Allow the metal to cool;

6, Heat treatment;

7, Chemical composition test, UT/MT test, mechanical test and so on.

8, Surface treatment and other requirement from customer.

Features of vertical roller mill rotor

1, Durable;

2, Excellent tensile strength;

3, Accurate level of tolerance;

4, Good dimensional accuracy;

5, Superb surface finishing;

6, Easy to use and install;

7, Abrasion resistant& realiable performance;

Order online

Fill out your message and submit it . Options with * must be filled in.

PRODUCTS

CONTACT

- Tel: +8615290747879

- Whatsapp: +8615290747879

- E-mail: casting@chaeng.co

- Skype : GreatWall1958