Newsroom

What are the high quality girth gears for rotary kiln

2020-06-24 | Editor:

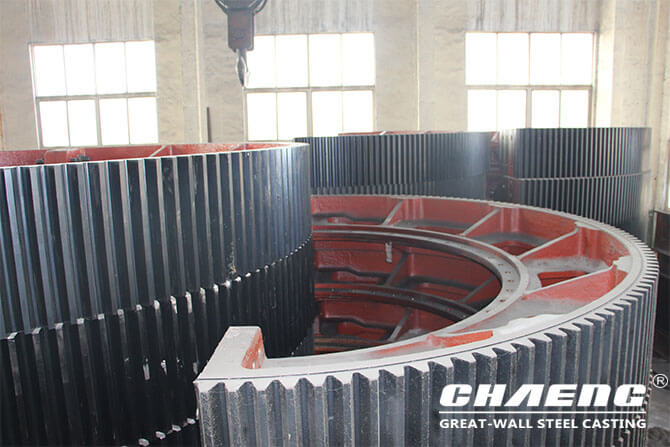

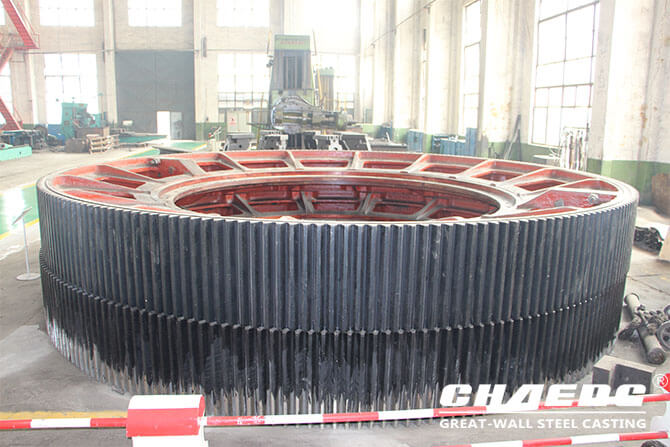

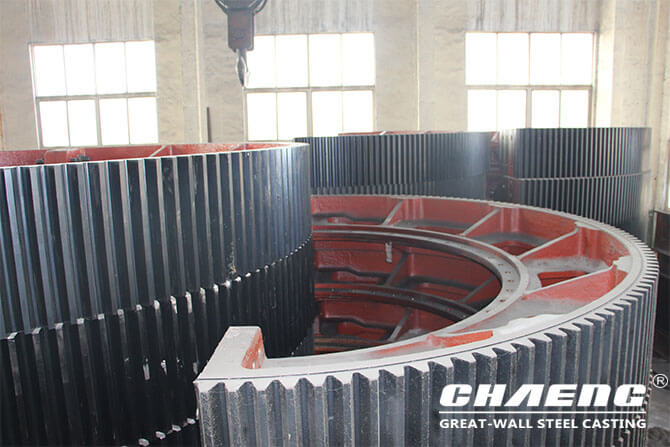

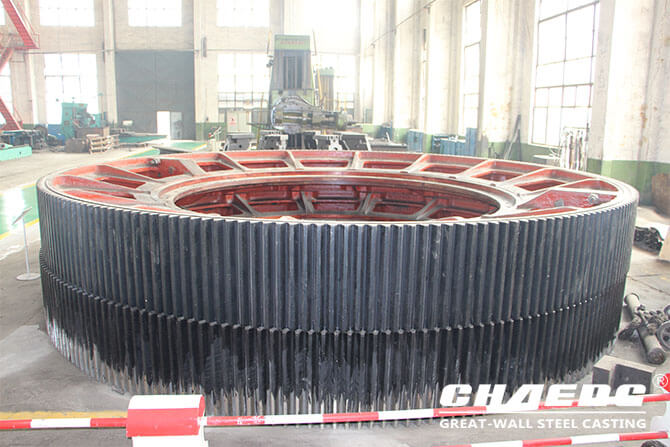

The girth gear, also known as the ring gear, is an important part of rotary kilns and ball mills. Its main function is to drive the entire cylinder to run for a long time. In order to ensure the use effect, it is very important to ensure the quality of the girth gear. So what conditions should a high-quality girth gear meet?

Generally, high-quality girth gear should meet the following three points:

1.High carrying capacity and smooth operation

Generally, high-quality girth gear should meet the following three points:

1.High carrying capacity and smooth operation

The girth gear should have the characteristics of high bearing capacity, smooth operation and low noise.

2.Simple structure, easy to maintain

The girth gear is a split structure with two halves, and the tooth width adopts a Y-shaped structure, which is convenient for transportation and installation and ensures good rigidity of the gear.

3.Advanced technology and superior rigidity performance

The material of the girth gear is ZG45 or ZG45CrMO high-quality alloy cast steel, which is stable for a long time and has a long service life.

The rotary kiln girth gear produced by CHAENG not only meets the above conditions, but also uses a unique heat treatment technology in casting, which optimizes the girth gear structure, improves the hardness, and greatly enhances the wear resistance and impact resistance of the gear.

2.Simple structure, easy to maintain

The girth gear is a split structure with two halves, and the tooth width adopts a Y-shaped structure, which is convenient for transportation and installation and ensures good rigidity of the gear.

3.Advanced technology and superior rigidity performance

The material of the girth gear is ZG45 or ZG45CrMO high-quality alloy cast steel, which is stable for a long time and has a long service life.

The rotary kiln girth gear produced by CHAENG not only meets the above conditions, but also uses a unique heat treatment technology in casting, which optimizes the girth gear structure, improves the hardness, and greatly enhances the wear resistance and impact resistance of the gear.

Advantages of steel castings provide by CHAENG:

In the early stage, we can formulate a specific process plan according to different customer needs; in the middle stage, strictly monitor each casting link; in the later stage, each product is strictly carried out nondestructive testing before leaving the factory, to prevent all defective products from leaving the factory.

In the early stage, we can formulate a specific process plan according to different customer needs; in the middle stage, strictly monitor each casting link; in the later stage, each product is strictly carried out nondestructive testing before leaving the factory, to prevent all defective products from leaving the factory.

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:Rotary kiln riding ring cast steel material

Next:What are the advantages of CHAENG as a slag ladle manufacturer

PRODUCTS

CONTACT

- Tel: +8615290747879

- Whatsapp: +8615290747879

- E-mail: casting@chaeng.co

- Skype : GreatWall1958