Newsroom

OEM customized large steel casting slag pot

2018-03-22 | Editor:

In the March, a batch of slag pots made by CHAENG were sent to there users in Ningbo, Anyang, Wuhan, etc.

In order to offer slag pots to customer satisfaction, CHAENG:

The key parts of CHAENG slag pot can reach level-2 testing standards of GB7233-2007, and its service life can be up to 6000 times of usage frequency. CHAENG has successfully cooperated with Shanghai Baosteel, Mittal Group, TaTa Group.

Advantages of CHAENG steel casting slag pot:

CHAENG is experienced manufacturer to supply large steel casting slag pot customized according to users’ drawings and demands. By now, CHAENG slag pots have been sold to the more than 50 countries and regions like United States, Mexico, Brazil, India, South Korea, Japan, Russia, and so on.

In order to offer slag pots to customer satisfaction, CHAENG:

- communicates fully with customers to make specific production plan

- numerically simulate the casting process by CAE software

- selects appropriate wooden mold for modeling design

- strictly control every procedure of mold, modelling, casting and testing

- strictly follows the national lever-2 detection standards, and executes 360° all-round nondestructive testing system

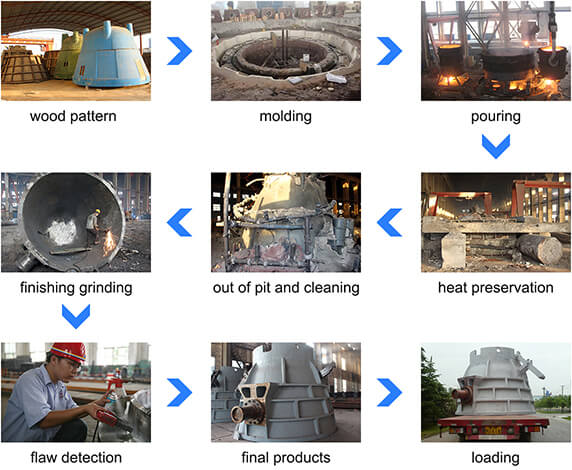

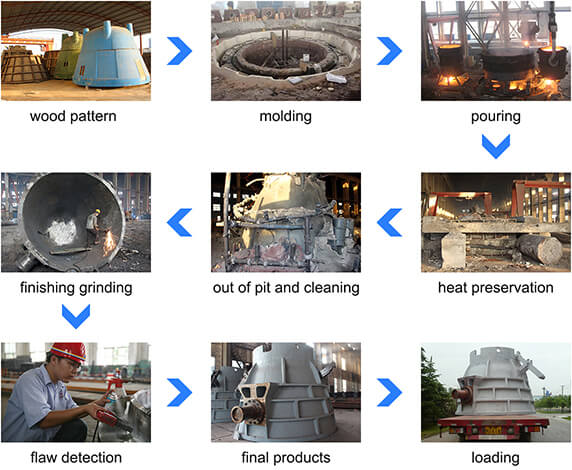

Process of CHAENG steel casting slag pot:

Process of CHAENG steel casting slag pot:

The key parts of CHAENG slag pot can reach level-2 testing standards of GB7233-2007, and its service life can be up to 6000 times of usage frequency. CHAENG has successfully cooperated with Shanghai Baosteel, Mittal Group, TaTa Group.

Advantages of CHAENG steel casting slag pot:

1. Many users: CHAENG slag pot / slag ladle is the common choice of many large world-renowned steel enterprises such as: Mittal Group, Tata Group, Taiwan Zhong Hua Iron& Steel Company, and so on.

2. Durable: CHAENG slag pot engineers adopt suitable material, customize and optimize the casting technology according to actual operating conditions. So CHAENG slag pots have: excellent high temperature mechanical properties, good thermal cracking resistance, stable manufacturing process and so on.

3. Longer service life: Up to 6000 times of usage frequency. First maintenance can be done 2~3 months later than similar products from other manufacturers.

4. Mature casting processes, rich experienced manufacturer: CHAENG, as a rich experienced manufacturer, has mature casting process and technical teams. CHAENG performs digital simulation of casting process by means of CAE before pouring, to achieve the optimization of slag pot casting process.

5. Level 2 of flaw detection: Ultrasonic and magnetic particle flaw detection level can reach the second level of standards.

6. Smooth side wall: Smooth inner wall of slag pot, to avoid adhering slag during operation.

7. Good appearance: CHAENG is quite skillful at shot blasting and sand blasting to ensure the good appearance of slag pot / slag ladle and improve paint adhesion.

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:Customized rolling mill housing steel casting manufacturer

PRODUCTS

CONTACT

- Tel: +8615290747879

- Whatsapp: +8615290747879

- E-mail: casting@chaeng.co

- Skype : GreatWall1958