| Weight | >1 Ton |

| Material | ASTM: 1055 / DIN: 42CrMo4 |

| Application | Rotary Kiln, Rotary Dryer, Rotary Drum |

| Customizable | Yes |

BUILDING MATERIALS INDUSTRY

kiln support roller

Introduction

The support roller (support wheel)bears the whole weight of the rotary kiln (including the barrel, inside bricks, heat exchange device inside the kiln, raw material, riding ring, and girth gear ring), which makes the barrel and the riding ring rotate smoothly Therefore, supporting rollers with strong endurance has become a vital standard to judge the quality of rotary kilns

Advantages

| Item | Introduction |

| 1.material | ZG55, ZG42CrMo, etc. |

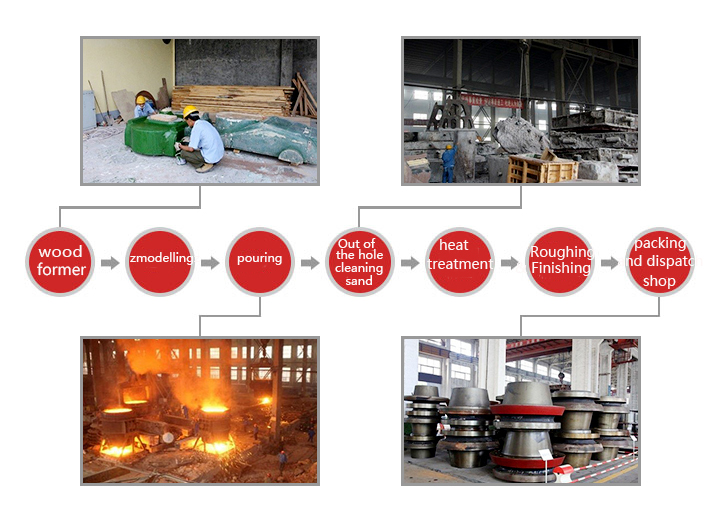

| 2.process | molding-pouring-cooling-shaking out-heat treatment |

| 3.Test | chemical composition, mechanical property, UT/MT and so on. |

| 4.Machine | rough machined, semi-finished machined, finished machined |

| 5.Certificate | ISO9001, OHSAS18001, ISO14001 |

| 6.Application | The products can be widely used in the area of building materials equipment, etc. |

| 7.Heat treatment | Normalized,Normalized and Tempered, Quench and Tempered. |

The Features:

1. Bear heavy load, good continuous operation.

CHAENG adopts quality steel materials, such as ZG55, ZG42CrMo, etc., so as to guarantee the quality but also has the advantages of bearing heavy load and good continuous operation.

CHAENG adopts quality steel materials, such as ZG55, ZG42CrMo, etc., so as to guarantee the quality but also has the advantages of bearing heavy load and good continuous operation.

2. Uses CAE software digital simulation technology to predict the casting quality and optimize the casting process.

3. By normalizing and tempering process, the surface hardness of the support roller is higher than 200HB, which ensures the quality of the rotary kiln support roller device.

Process

Case

Supporting rollers from CHAENG were installed on rotary kilns of many customers with reliable performance.

Note:

CHAENG can produce all types of supporting wheels according to customers’ drawings and sizes. You are warmly welcomed to visit our company!

Order online

Fill out your message and submit it . Options with * must be filled in.

PRODUCTS

CONTACT

- Tel: +8615290747879

- Whatsapp: +8615290747879

- E-mail: casting@chaeng.co

- Skype : GreatWall1958