| Weight | 20-132 t |

| Material | ASTM: A570 / BS: S235JR |

| Application | Vertical Roller Mill |

| Customizable | Yes |

Cement & Mining

Grinding Table of Vertical Mill

Introduction

Grinding table is one of key parts of vertical roller mill. It includes drag rings, lining plate and base. The optimization and improvement are made basing on traditional grinding table casting technology, that the most advanced sodium silicate-bonded sand molding technology, to overcome deficiencies in structure and make the grinding base bear force equivalently. All these measures avoid material’s washout problem on no-wear-resisting surface. Advantages

1.Grinding tables have the features of high hardness, good anti-cracking.

2.We carry out grinding table dressing and finishing machining by arc air gouging and shot-blasting, which can guarantee the quality of steel castings.

3.Before delivery, all the grinding tables shall have NDT inspection several times as per perfect inspection flow. Any defective product is forbidden to leave factory.

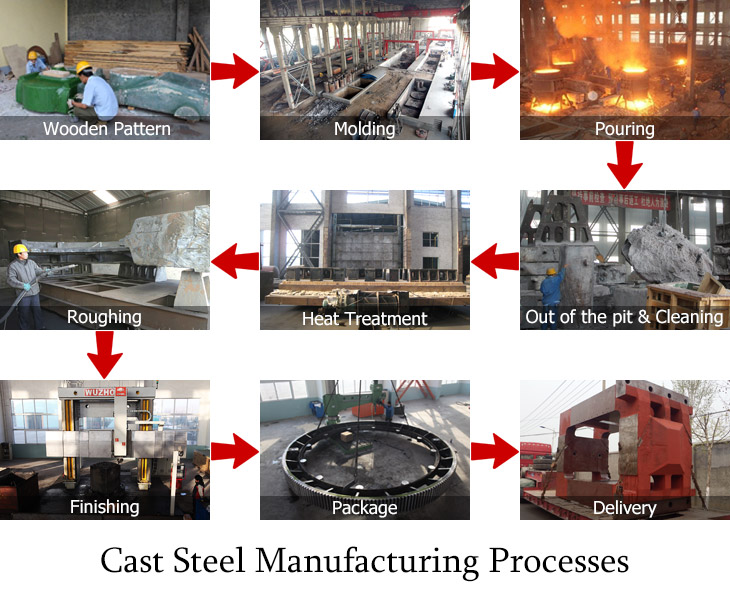

Process

Case

Through many years’ efforts and development, Great Wall Casting’s

customers are all over China and Europe, America, Germany and other countries.

The good service and product quality makes Great Wall a strategic partner with

world famous large machinery manufacturers, Denmark FLSmidth, Xinxiang Great

Wall Machinery, etc.

Order online

Fill out your message and submit it . Options with * must be filled in.

CONTACT

- Tel : +86-371-53379608

- Fax : +86-371-55019608

- E-mail :greatwallcasting@gmail.com